-

Industrial Abrasives

-

Coated Abrasives

-

Bonded Abrasives

-

Roller Ball Bearing

-

Carbide Tool Inserts

-

Resin Bond Abrasives

-

Metal Bonded Abrasives

-

Bearing Measuring Instrument

-

Vitrified Bonded Abrasives

-

Electroplated Tools

-

Bearing Spare Parts

-

Diamond Slurry

-

Single Crystalline Diamond

-

Precision Measuring Instruments

-

Salt Bath Nitriding

-

Semiconductor Consumables

-

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You.

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You. -

RomanWe tested the products. They are really good. We will place a big order.

RomanWe tested the products. They are really good. We will place a big order.

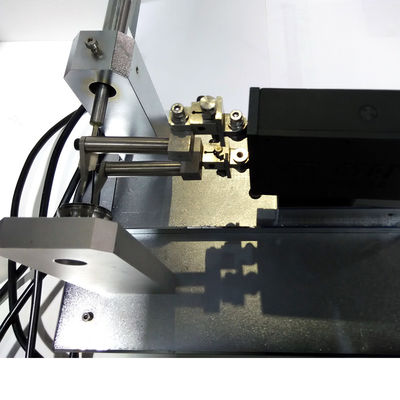

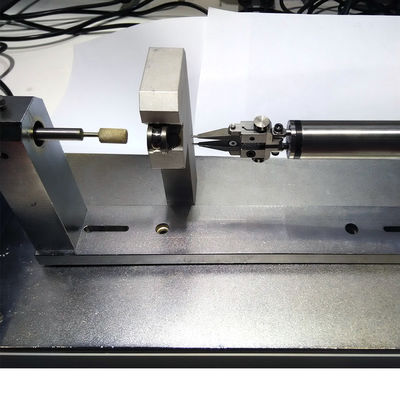

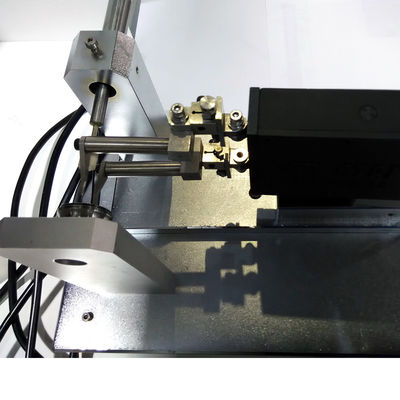

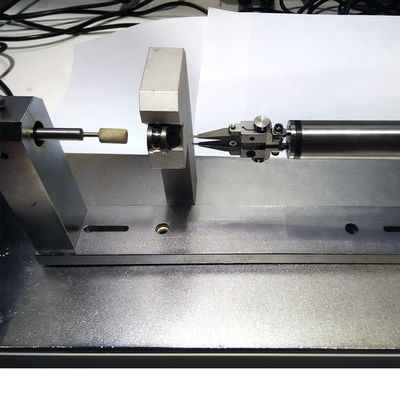

Online Precision Measuring Instruments Diameter Testing

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Highlight | Online Precision Measuring Instruments,Measuring Instruments Diameter Testing,Diameter Precision Measuring Instruments |

||

|---|---|---|---|

Online Precision Measuring Instruments

The in process measuring system (ZD series) produced by CTRI employs internationally advanced in-process measuring technology in combination with independent R & D. CTRI has over 30 years’ manufacturing experience in measuring products for in-process application. The in-process measuring gauges developed have been mainly applied in fine grinding of various spindles, bearing parts, inner hole of automobile gear, plain grinding and other processing fields.

Increased productivity and reduced maintenance costs are key elements of the industrial process.The optimum solution is real-time control of work piece processing and machine conditions. ZD series in process measuring system employs relative measurement principle to compare different physical dimensions between work piece and the standard work-piece, giving logical control signals to the grinding machine through pre-fixed values to ensure smooth machining process. ZD series products present characteristics such as high measuring accuracy,strong durability and wide ranges of application, making it an ideal in-process measuring system in precision grinding process.

| Configuration | Parameters |

| Amplifier Display | Digital display |

| Correction Value | Digital display |

| I/O | Relay/ Opto-isolated |

| Power supply |

100-110VAC; 200-220VAC Frequency: 50HZ |

| Input/Output Interface |

10 pin clamped inlet socket 16 pin rectangular outlet socket |

| NC interface wire with the machine | 4m |

| Power line | 3m |

| Additional function | Retraction (S)/Memory function (J) |

| Physical dimension |

214(W)*140(H)*172(D) (the height of knobs is not included)

|

| Application range | Inner and outer diameter |

Technical Specification

| Structure | Cabinet |

| Number of channels |

1-2 channels ( Air-Gap inductive measuring heads) |

| Measuring cycle | In-process grinding |

| Display range | +500um——-300um |

| Correction Value Range |

1um scale +59um——-59um 0.5um scale +20um——-20um 0.1um scale +20um——-20um |

| Correction scale | 1um,0.5um,0.1um |

|

Display Resolution

|

0.3 um |

| Electrical Stability | 0.8um/6h |

| Number of Output Logical Control | 4 |

Basic Configuration and Technical Specification

| Number and types of sensor | 2×AIR GAP |

| Measuring Range | 400um |

| Repetitive Precision | ≤1um |

| Pre-travel | 180±20um |

| Over-travel | ≥500um |

| Damping function | Yes |

| Micrometric Setting | Dovetail slide |

| Measuring contact | Diamond |

| Measuring smooth / interrupted surface | Optional |

| Measurement Force | 0.9N |

| Cable | 3m |