-

Industrial Abrasives

-

Coated Abrasives

-

Bonded Abrasives

-

Roller Ball Bearing

-

Carbide Tool Inserts

-

Resin Bond Abrasives

-

Metal Bonded Abrasives

-

Bearing Measuring Instrument

-

Vitrified Bonded Abrasives

-

Electroplated Tools

-

Bearing Spare Parts

-

Diamond Slurry

-

Single Crystalline Diamond

-

Precision Measuring Instruments

-

Salt Bath Nitriding

-

Semiconductor Consumables

-

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You.

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You. -

RomanWe tested the products. They are really good. We will place a big order.

RomanWe tested the products. They are really good. We will place a big order.

618 Series 619 Series Deep Groove Ball Bearing Super Thin P4 P2 P0

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model NO. | 61918 | Inner Diameter | 17-110mm |

|---|---|---|---|

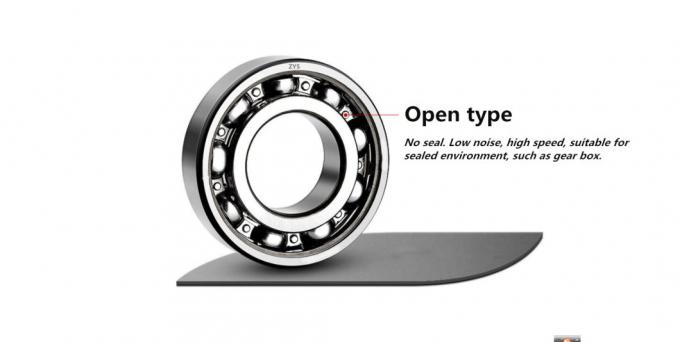

| Accuracy Class | P4/P2/P0 | Sealing Type | Open RS Zz 2RS 2rz |

| Rolling Body | Ball Bearings | The Number Of Rows | Single |

| Spherical | Non-Aligning Bearings | Outer Dimension | 35-280mm |

| Application | Pump, Motorcycle, Washing Machine, Car | Brand | CAEC, OEM, Neutral |

| Bearing Material | Gcr15, Chrome Steel, Stainless Steel, Carbon Steel | Quality Control | ABEC-1, ABEC-3, Z1V1, Z2V2, Z3V3 |

| Bearing Series | 6000,6200,6300,6400, 16000 Series Bearings | Use | For Industry& Mechanical&Agriculture, Auto |

| Field | Conveyor, Diesel Hydraulic, Pump,Car Accessories | Transport Package | Cases And Pallets Or As Customer′s Requirment |

| Specification | High Quality | Trademark | CAEC |

| Origin | Luoyang, Henan, China | HS Code | 8482102000 |

| Supply Ability | 200000/Month | Contact Angle | 0 |

| Aligning | Non-Aligning Bearing | Separated | Separated |

| Rows Number | Single | Load Direction | Radial Bearing |

| Material | Bearing Steel | Samples | US$ 0.1/Piece 1 Piece(Min.Order) | Request Sample |

| Customization | Available | Customized Request | ||

| Highlight | 619 Series Deep Groove Ball Bearing,618 Series Deep Groove Ball Bearing,618 619 deep groove roller bearing |

||

Super thin series deep groove ball bearing products are divided into 2 series: 618 series, 619 series. These series bearings can save space, reduce weight, significantly reduce friction, and offer good rotation accuracy. It also can effectively reduce the external dimensions of the machine and reduce production cost without affecting bearing performance and service life.

►Working principle of CAEC deep groove ball bearing

It mainly bears radial load, and also can bear axial load and radial load at the same time. When it only bears radial load, the contact angle is zero. When the deep groove ball bearing has a large radial clearance, it has the performance of angular contact bearing and can withstand large axial load. The friction coefficient of the deep groove ball bearing is very small, and the limit speed is also very high.

►Characteristics of CAEC deep groove ball bearing

CAEC Deep groove ball bearings are suitable for high speed operation, and they are very durable without frequent maintenance. This kind of bearing has the characteristics of small friction coefficient, high limit speed, various sizes and forms; they are used in precision instruments, low noise motor, automobile, motorcycle and general machinery and other industries. It is one of the most widely used bearing in mechanical industry. It mainly bears radial load, and also can bear a certain amount of axial load.

►Application of CAEC deep groove ball bearing

►Technical parameter of CAEC deep groove ball bearing

| Bearing Model | Dimension | Basic Load rating (kN) | Weight (kg) | |||||||||||

| Standard type | shield | seal | With snap ring groove | With snap ring | d | D | B | rsmin | D2 (max) | F max | Cr | Cor | ||

| 61905 | ZZ | 2RZ | 2RS | N | NR | 25 | 42 | 9 | 0.3 | 44.8 | 0.85 | 6.63 | 4.00 | 0.045 |

| 61906 | ZZ | 2RZ | 2RS | N | NR | 30 | 47 | 9 | 0.3 | 49.8 | 0.85 | 7.28 | 4.55 | 0.051 |

| 61907 | ZZ | 2RZ | 2RS | N | NR | 35 | 55 | 10 | 0.6 | 57.8 | 0.85 | 9.56 | 6.20 | 0.080 |

| 61908 | ZZ | 2RZ | 2RS | N | NR | 40 | 62 | 12 | 0.6 | 64.8 | 0.85 | 13.8 | 9.30 | 0.120 |

| 61909 | ZZ | 2RZ | 2RS | N | NR | 45 | 68 | 12 | 0.6 | 70.8 | 0.85 | 10.1 | 6.70 | 0.140 |

| 61910 | ZZ | 2RZ | 2RS | N | NR | 50 | 72 | 12 | 0.6 | 74.8 | 0.85 | 14.6 | 10.4 | 0.140 |

| 61911 | ZZ | 2RZ | 2RS | N | NR | 55 | 80 | 13 | 1 | 84.4 | 1.12 | 16.0 | 13.2 | 0.181 |

| 61912 | ZZ | 2RZ | 2RS | N | NR | 60 | 85 | 13 | 1 | 89.4 | 1.12 | 16.4 | 14.2 | 0.195 |

| 61913 | ZZ | 2RZ | 2RS | N | NR | 65 | 90 | 13 | 1 | 94.4 | 1.12 | 16.0 | 15.0 | 0.196 |

| 61914 | ZZ | 2RZ | 2RS | N | NR | 70 | 100 | 16 | 1 | 104.4 | 1.12 | 23.7 | 21.1 | 0.342 |

| 61915 | ZZ | 2RZ | 2RS | N | NR | 75 | 105 | 16 | 1 | 110.7 | 1.12 | 24.3 | 22.5 | 0.355 |

| 61916 | ZZ | 2RZ | 2RS | N | NR | 80 | 110 | 16 | 1 | 115.7 | 1.12 | 24.9 | 23.9 | 0.375 |

| 61917 | ZZ | 2RZ | 2RS | N | NR | 85 | 120 | 18 | 1.1 | 125.7 | 1.12 | 31.9 | 29.7 | 0.507 |

| 61918 | ZZ | 2RZ | 2RS | N | NR | 90 | 125 | 18 | 1.1 | 130.7 | 1.12 | 32.8 | 31.5 | 0.533 |

| 61919 | ZZ | 2RZ | 2RS | N | NR | 95 | 130 | 18 | 1.1 | 135.7 | 1.12 | 33.7 | 33.3 | 0.558 |

| 61920 | ZZ | 2RZ | 2RS | N | NR | 100 | 140 | 20 | 1.1 | 145.7 | 1.7 | 42.7 | 41.9 | 0.774 |

| 61921 | ZZ | 2RZ | 2RS | N | NR | 105 | 145 | 20 | 1.1 | 150.7 | 1.7 | 43.9 | 44.3 | 0.808 |

| 61922 | ZZ | 2RZ | 2RS | N | NR | 110 | 150 | 20 | 1.1 | 155.7 | 1.7 | 43.6 | 44.4 | 1.00 |

| 61924 | ZZ | 2RZ | 2RS | N | NR | 120 | 165 | 22 | 1.1 | 171.5 | 1.7 | 53.0 | 53.9 | 1.09 |

| 61926 | ZZ | 2RZ | 2RS | N | NR | 130 | 180 | 24 | 1.5 | 186.5 | 1.7 | 65.1 | 67.2 | 1.50 |

| 61928 | ZZ | 2RZ | 2RS | N | NR | 140 | 190 | 24 | 1.5 | 196.5 | 1.7 | 66.6 | 71.2 | 1.59 |

| 61930 | ZZ | 2RZ | 2RS | - | -- | 150 | 210 | 28 | 2 | -- | - | 84.7 | 90.2 | 2.45 |

| 61932 | ZZ | 2RZ | 2RS | - | -- | 160 | 220 | 28 | 2 | -- | - | 86.9 | 95.5 | 2.59 |

| 61934 | ZZ | 2RZ | 2RS | - | -- | 170 | 230 | 28 | 2 | -- | - | 88.8 | 100 | 2.73 |

| 61936 | ZZ | 2RZ | 2RS | -- | - | 180 | 250 | 33 | 2 | -- | -- | 118 | 133 | 4.06 |

| 61938 | ZZ | 2RZ | 2RS | -- | - | 190 | 260 | 33 | 2 | -- | -- | 117 | 133 | 4.22 |

| 61940 | ZZ | 2RZ | 2RS | -- | - | 220 | 300 | 38 | 2.1 | -- | - | 152 | 178 | 6.34 |

| 61948 | ZZ | 2RZ | -- | -- | - | 240 | 320 | 38 | 2.1 | -- | - | 154 | 190 | 8.49 |

| 61952 | ZZ | 2RZ | - | -- | - | 260 | 360 | 46 | 2.1 | -- | - | 204 | 255 | 14 |

| 61956 | ZZ | 2RZ | - | -- | - | 280 | 380 | 46 | 2.1 | -- | - | 209 | 272 | 15.1 |

| 61960 | ZZ | 2RZ | - | -- | - | 300 | 420 | 56 | 3 | -- | - | 269 | 370 | 23.9 |

| 61809 | ZZ | 2RZ | 2RS | N | NR | 45 | 58 | 7 | 0.3 | 60.8 | 0.85 | 4.65 | 4.32 | 0.040 |

| 61810 | ZZ | 2RZ | 2RS | N | NR | 50 | 65 | 7 | 0.3 | 67.8 | 0.85 | 6.60 | 6.10 | 0.043 |

| 61811 | ZZ | 2RZ | 2RS | N | NR | 55 | 72 | 9 | 0.3 | 74.8 | 0.85 | 9.10 | 8.40 | 0.070 |

| 61812 | ZZ | 2RZ | 2RS | N | NR | 60 | 78 | 10 | 0.3 | 82.7 | 1.12 | 9.10 | 8.70 | 0.093 |

| 61813 | ZZ | 2RZ | 2RS | N | NR | 65 | 85 | 10 | 0.6 | 89.4 | 1.12 | 11.9 | 11.5 | 0.130 |

| 61814 | ZZ | 2RZ | 2RS | N | NR | 70 | 90 | 10 | 0.6 | 94.4 | 1.12 | 12.1 | 11.9 | 0.138 |

| 61815 | ZZ | 2RZ | 2RS | N | NR | 75 | 95 | 10 | 0.6 | 99.4 | 1.12 | 12.5 | 12.8 | 0.147 |

| 61816 | ZZ | 2RZ | 2RS | N | NR | 80 | 100 | 10 | 0.6 | 104.4 | 1.12 | 12.7 | 13.3 | 0.155 |

| 61817 | ZZ | 2RZ | 2RS | N | NR | 85 | 110 | 13 | 1 | 115.7 | 1.12 | 19.2 | 19.8 | 0.245 |

| 61818 | ZZ | 2RZ | 2RS | N | NR | 90 | 115 | 13 | 1 | 120.7 | 1.12 | 19.5 | 20.5 | 0.258 |

| 61819 | ZZ | 2RZ | 2RS | N | NR | 95 | 120 | 13 | 1 | 125.7 | 1.12 | 19.8 | 21.3 | 0.270 |

| 61820 | ZZ | 2RZ | 2RS | N | NR | 100 | 125 | 13 | 1 | 130.7 | 1.12 | 20.1 | 22.0 | 0.303 |

| 61821 | -- | 2RZ | 2RS | N | NR | 105 | 130 | 13 | 1 | 135.7 | 1.12 | 20.3 | 22.7 | 0.312 |

| 61822 | -- | 2RZ | 2RS | N | NR | 110 | 140 | 16 | 1 | 145.7 | 1.7 | 22.5 | 24.5 | 0.509 |

| 61824 | -- | 2RZ | 2RS | N | NR | 120 | 150 | 16 | 1 | 155.7 | 1.7 | 24.0 | 28.0 | 0.529 |

| 61826 | -- | 2RZ | 2RS | N | NR | 130 | 165 | 18 | 1.1 | 171.5 | 1.7 | 24.4 | 28.0 | 0.775 |

| 61828 | -- | 2RZ | 2RS | N | NR | 140 | 175 | 18 | 1.1 | 181.5 | 1.7 | 39.2 | 46.0 | 0.784 |

| 61830 | -- | 2RZ | 2RS | N | NR | 150 | 190 | 20 | 1.1 | 196.5 | 1.7 | 49.1 | 57.1 | 1.11 |

| 61832 | -- | 2RZ | 2RS | N | NR | 160 | 200 | 20 | 1.1 | 206.5 | 1.7 | 45.2 | 55.1 | 1.18 |

| 61834 | -- | 2RZ | 2RS | -- | -- | 170 | 215 | 22 | 1.1 | -- | -- | 51.2 | 63.3 | 1.65 |

| 61836 | -- | 2RZ | 2RS | -- | -- | 180 | 225 | 22 | 1.1 | -- | -- | 62.3 | 75.9 | 1.62 |

| 61838 | -- | 2RZ | 2RS | -- | -- | 190 | 240 | 24 | 1.5 | -- | -- | 75.1 | 91.6 | 2.10 |

| 61840 | -- | 2RZ | 2RS | -- | -- | 200 | 250 | 24 | 1.5 | -- | -- | 74.2 | 91.2 | 2.18 |

| 61848 | ZZ | 2RZ | -- | -- | -- | 240 | 300 | 28 | 2 | -- | -- | 98.5 | 137 | 4.48 |

| 61852 | ZZ | 2RZ | -- | -- | -- | 260 | 320 | 28 | 2 | -- | -- | 101 | 148 | 4.84 |

| 61856 | ZZ | 2RZ | -- | -- | -- | 280 | 350 | 33 | 2 | -- | -- | 133 | 191 | 7.2 |

| 61860 | ZZ | 2RZ | -- | -- | -- | 300 | 380 | 38 | 2 | -- | -- | 166 | 233 | 10.3 |

►Why choose CAEC bearing:

CAEC has an independent R&D center and a core technology system with independent intellectual property rights. CAEC technical team and R&D equipment scale are at the forefront of the bearing industry. CAEC has many scientific research, testing and service institutions such as the National Bearing Quality Supervision and Inspection Center and the National Bearing Accreditation Laboratory. CAEC has achieved 908 major scientific research projects and has 792 authorized patents.

Simulation analysis and design technology: CAEC has a post-doctoral research station, an experienced team of domestic and foreign experts, complete bearing professional analysis and finite element analysis software, which can systematically analyze and design the mechanics, kinematics and dynamics properties of bearings and bearing components.

Material technology: CAEC specializes in the research and development of bearing special steel, forming and heat treatment technology, bearing lubrication and sealing materials to ensure that the bearings can meet the requirements of various complex working conditions such as long life, impact resistance, heavy load, high and low temperature.

Simulation bench test technology: CAEC possesses test technical specifications, test equipment, and test equipment development capabilities and test data processing and analysis capabilities for various types of bearings under various working conditions, providing strong support for customer product development.

Professional application technical services: CAEC has more than 380 engineering and technical personnel in bearing-related disciplines, and maintains a leading position in bearing design, basic theoretical research, lubrication technology, metal and non-metal materials, testing, and industrial standards. CAEC professional service team provides customers with systematic bearing application technology solutions including bearing selection, design, materials, testing, and process equipment.

►Package of deep groove ball bearing

Q: Are you trading company or manufacturer?

A: CAEC is bearing manufacturer, the only first-class comprehensive research institute in China bearing industry.

Q: How do you control quality of bearing?

A: CAEC has established quality control systems for each kind of bearing and spindle. All products and services passed ISO9001-2008 Quality Certificate.

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic tube+ carton+ pallet). Accept design package when OEM.

Q: How long is the delivery time?

A: It will take about 10 to 40 days, depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have the forwarder.

Q: Is sample avaiable?

A: Yes, sample order is acceptable.

Q: Can we use our own LOGO or design on bearings?

A: Yes. OEM is acceptable. We can design the bearing with your requirements and use your own LOGO and package design.