-

Industrial Abrasives

-

Coated Abrasives

-

Bonded Abrasives

-

Roller Ball Bearing

-

Carbide Tool Inserts

-

Resin Bond Abrasives

-

Metal Bonded Abrasives

-

Bearing Measuring Instrument

-

Vitrified Bonded Abrasives

-

Electroplated Tools

-

Bearing Spare Parts

-

Diamond Slurry

-

Single Crystalline Diamond

-

Precision Measuring Instruments

-

Salt Bath Nitriding

-

Semiconductor Consumables

-

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You.

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You. -

RomanWe tested the products. They are really good. We will place a big order.

RomanWe tested the products. They are really good. We will place a big order.

G10 Ball Bearing Balls Bearing Spare Parts Silicon Nitride Ceramic Balls

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model NO. | 1.588mm | Shape | Polish Round Bearing Steel Ball |

|---|---|---|---|

| Grade | G10-G1000 Chrome Steel Ball | Application | Bearing, Solid Bicycle, Motor, Machinery, Tools |

| Product Name | High-Carbon Stainless Chrome Steel Ball | Structure | Solid Chrome Steel Ball |

| Size Range | 0.5mm-180mm Chrome Steel Ball | Accuracy Grade | G3 G5 G10 G25 G40 |

| Ball Material | Steel Ball, Ceramic Ball, Si3n4 ,Zro2 | Color | White, Black |

| Compressive Strength | Above 3500 | Use Upper Limit Temperature | 800-1250 |

| Vickers Hardness | 1400~1800 | Density | 3.19~3.3 |

| Use | Light Duty Bearing,Conveyer Belt, Bicycle | Transport Package | Cases And Pallets Or As Customer′s Requirment |

| Specification | 38.1-180mm | Trademark | CAEC/OEM |

| Origin | Luoyang, Henan, China | Supply Ability | 400000/Month |

| Customized | Non-Customized | Certification | CE, ISO |

| Standard Parts | Yes | Universal | Yes |

| Material | Galvanized Steel, Plastic, Brass Steel And Others | Hardness | 58-65 HRC Bearing Ball |

| Samples | US$ 0.1/Piece | Customization | Available | Customized Request |

| Highlight | G10 Ball Bearing Balls,Balls Bearing Spare Parts,Silicon Nitride Ceramic Balls |

||

Rolling Element Precision Bearing Ball Silicon Nitride Ceramic balls G10 for Bearing

►The development history of CAEC silicon nitride ceramic balls:

Use laser confocal microscope and ultrasonic scanning microscope for particle size analysis, impurity content analysis, oxygen and nitrogen content analysis, phase composition analysis.

| Item | Materials class | ||||

| I | II | III | |||

| Property | Bending strength σ3.40 (Mpa) | 900 | 800 | 600 | |

| Crushing load ratio (%) | 35 | 35 | 30 | ||

| Hardness (HV10) | 1580 | 1480 | 1380 | ||

| Fracture toughness (Mpa.m1/2) | 6.0 | 5.0 | 5.0 | ||

| Maximum limit of microstructure | Pore size (μm) | 10 | 10 | 25 | |

| Porosity (%) | 0.02 | 0.06 | 0.06 | ||

| Crystal phase (μm) | 10 | 10 | 25 | ||

| The second ceramic phase (μm) | 25 | 25 | 25 | ||

| Maximum amount of inclusions per square centimeter of cross section |

Range 200 (μm) | 0 | 0 | 1 | |

| Range 100~200 (μm) | 0 | 1 | 2 | ||

| Range 50~100 (μm) | 1 | 2 | 4 | ||

| Range 20~50 (μm) | 4 | 8 | 16 | ||

| Application of Si3N4 ceramic ball | ||||

| G3 | G5 | G10, G16 | G20, G28, G40 | |

| Class I | High speed power equipment | Main drive bearing |

||

| Class II | Vacuum equipment, high speed instrument, mechanical devices, |

Motor | Testing ball, separating ball | |

| Class III | Sport, entertainment, food processing |

Mechanical devices | ||

| Si3N4 ceramic ball specifications | |||||

| Nominal diameter of ceramic ball | Nominal diameter of ceramic ball | Nominal diameter of ceramic ball | |||

| mm | in | mm | in | mm | in |

| 0.794 | 1/32 | 0.8 | 1 | ||

| 1.588 | 1/16 | 2 | 2.381 | 3/32 | |

| 2.5 | 3 | 3.969 | 5/32 | ||

| 4 | 4.5 | 4.762 | 3/16 | ||

| 5 | 5.5 | 5.556 | 7/32 | ||

| 5.953 | 15/64 | 6 | 6.35 | 1/4 | |

| 6.5 | 6.747 | 17/64 | 7 | ||

| 7.144 | 9/32 | 7.5 | 7.938 | 5/16 | |

| 8.731 | 11/32 | 9.525 | 3/8 | 11.112 | 7/16 |

| 12.303 | 31/64 | 12.7 | 1/2 | 13.494 | 17/32 |

| 14.288 | 9/16 | 15.081 | 19/32 | 15.875 | 5/8 |

| 19.05 | 3/4 | 25.4 | 1 | 31.75 | 1 1/4 |

►ZYS Manufacturing capacity of Si3N4 ceramic ball:

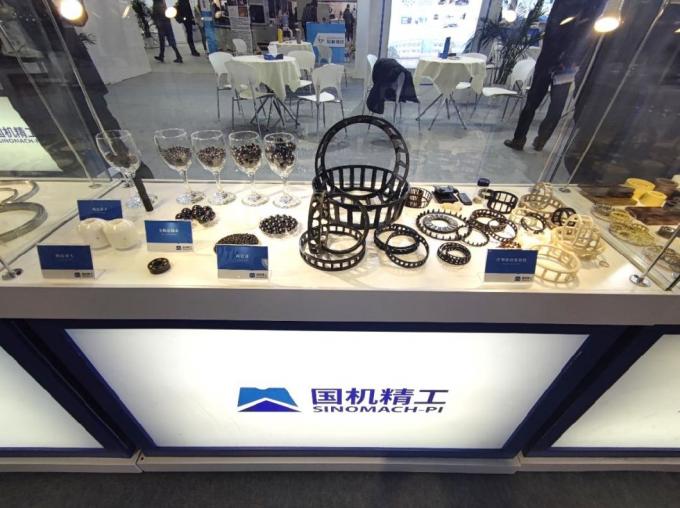

►Exhibition of Si3N4 ceramic ball: