-

Industrial Abrasives

-

Coated Abrasives

-

Bonded Abrasives

-

Roller Ball Bearing

-

Carbide Tool Inserts

-

Resin Bond Abrasives

-

Metal Bonded Abrasives

-

Bearing Measuring Instrument

-

Vitrified Bonded Abrasives

-

Electroplated Tools

-

Bearing Spare Parts

-

Diamond Slurry

-

Single Crystalline Diamond

-

Precision Measuring Instruments

-

Salt Bath Nitriding

-

Semiconductor Consumables

-

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You.

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You. -

RomanWe tested the products. They are really good. We will place a big order.

RomanWe tested the products. They are really good. We will place a big order.

Microporous Bakelite Cage Bearing Spare Parts 71902 Non Customized

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model NO. | 71902 | Application | Bearing |

|---|---|---|---|

| Product Name | Microporous Bakelite Cage | Origin | Luoyang, Henan, China |

| Supply Ability | 400000/Month | Customized | Non-Customized |

| Certification | CE, ISO | Standard Parts | Yes |

| Universal | Yes | ||

| Highlight | Bearing Microporous Bakelite Cage,71902 Bearing Spare Parts,Bakelite Cage Bearing Spare Parts |

||

Microporous bakelite cage

Technical parameters of Microporous bakelite cages:

Inner diameter size : Ф25mm~Ф90mm

Outer diameter size : Ф35mm~Ф100mm

Applicable speed : 1000~60000r/min

Applicable temperature : -50~+120℃

Material: Microporous bakelite cage is made of cotton cloth as the base material, phenolic resin as the adhesive, and thermal reactive foaming agent as the pore forming agent and then becomes the tubular material after hot rolling and post-curing technology.

Working principle of microporous bakelite cages: After being processed into the cage and immersed in lubricating oil, we can transport the lubricating oil to the cage surface by capillary action of cotton fiber, and the controllable lubricating oil can be supplied to the working part of the bearing during bearing operation to achieve high precision and long service life of the bearing.

| Material grade | Ring tensile strength/ MPa | Porosity/% | Hole radius/μm | Applicable situation |

| Microporous bakelite | ≥45 | 10%~20a% | 1.0~3.0 | Medium and high speed |

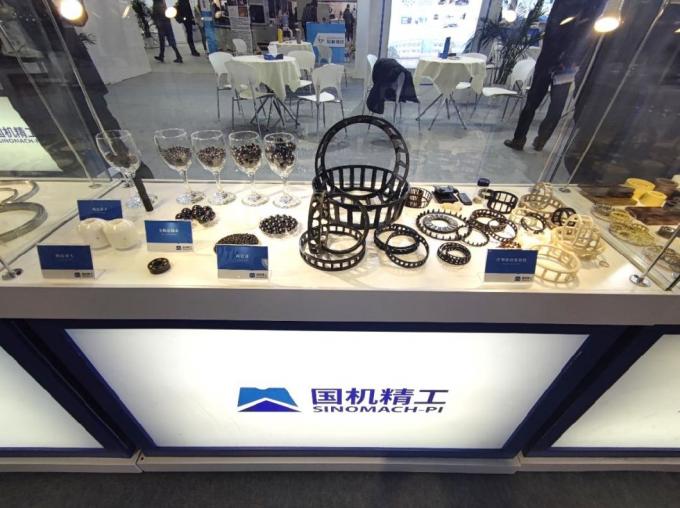

►Exhibition of Microporous bakelite cage: