-

Industrial Abrasives

-

Coated Abrasives

-

Bonded Abrasives

-

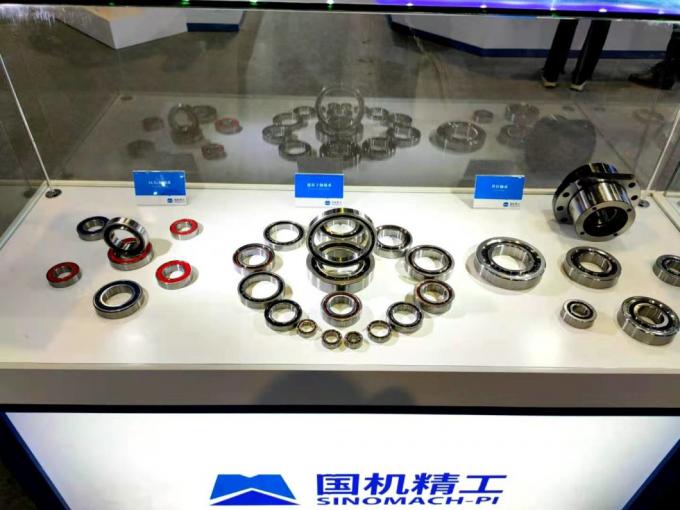

Roller Ball Bearing

-

Carbide Tool Inserts

-

Resin Bond Abrasives

-

Metal Bonded Abrasives

-

Bearing Measuring Instrument

-

Vitrified Bonded Abrasives

-

Electroplated Tools

-

Bearing Spare Parts

-

Diamond Slurry

-

Single Crystalline Diamond

-

Precision Measuring Instruments

-

Salt Bath Nitriding

-

Semiconductor Consumables

-

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You.

MariaThe quality is very good and stable. We are happy with the team we work with. Hope we will continue to cooperate in business for many years. Thank You. -

RomanWe tested the products. They are really good. We will place a big order.

RomanWe tested the products. They are really good. We will place a big order.

71912 Roller Ball Bearing Single Row Angular Contact Ball Bearing

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Model NO. | 71912 | Ball Bearings | Angular Contact Ball Bearing |

|---|---|---|---|

| Inner Diameter | 3-360mm | Accuracy Grade | ABEC 7 Or ABEC 9 P0, P6, P5, P4, P2 |

| Sealing Type | Sealed Or Not | Rolling Body | Ball Bearings |

| The Number Of Rows | Single/Double | Spherical | Non-Aligning Bearings |

| Outer Dimension | 8-480mm | Application | Machine Tool, Spindle, Motor, Separater |

| Advantages | High Speed, High Precision,High Quality | Use | Automobile, Car, Motorcycle, Ball Screw,Engine,Gas |

| OEM | Acceptable | Delivery Period | Within 7 Days |

| Other Contact Angle | 15,25,40 | Transport Package | Cases And Pallets Or As Customer′s Requirment |

| Specification | Customized For Angular Contact Ball Bearing | Trademark | CAEC, OEM, Neutral |

| Origin | Luoyang, Henan, China | HS Code | 8482102000 |

| Supply Ability | 1000000 PCS/Year | Contact Angle | 40 |

| Aligning | Non-Aligning Bearing | Separated | Unseparated |

| Rows Number | Single/Double | Load Direction | Axial And Radial |

| Material | Bearing Steel | Samples | US$ 5/Piece |

| Customization | Available | Customized Request | ||

| Highlight | 71912 Roller Ball Bearing,Single Row Angular Contact Ball Bearing,71912 Angular Contact Ball Bearing |

||

718, 719,70, 72 series single row angular contact ball bearing

A new generation of precision angular contact ball bearings have been developed by our company for the machine tool spindle. Comparing with general precision bearings, angular contact bearings are greatly improved in terms of rotation accuracy, limit speed, carrying capacity and reliability; and the size range is also wider. We are able to produce 718 series, 719 series, 70 series and 72 series high speed bearings for machine tool, motor, spindle, power tool and can also develop new products for special application conditions according to customers' needs and provide services for customers.

Dimension table of angular contact ball bearing:

|

Bearing designation ZYS |

Boundary dimension | α=15°(C) | α=25°(AC) | |||||||||||||||||||||||||||

| Rated load | Limit speed | Rated load | Limit speed | |||||||||||||||||||||||||||

| d | D | B | Cr | C0r | Grease | Oil | Cr | C0r | Grease | Oil | ||||||||||||||||||||

| mm | KN | r/min | KN | r/min | ||||||||||||||||||||||||||

| 71907 | 35 | 55 | 10 | 11 | 10.9 | 26000 | 40000 | 10.4 | 10.3 | 20000 | 34000 | |||||||||||||||||||

| 71908 | 40 | 62 | 12 | 14 | 14.2 | 20000 | 34000 | 13.3 | 13.5 | 18000 | 30000 | |||||||||||||||||||

| 71909 | 45 | 68 | 12 | 14.7 | 16.1 | 18000 | 30000 | 13.9 | 15.2 | 17000 | 28000 | |||||||||||||||||||

| 71910 | 50 | 72 | 12 | 19 | 21.2 | 17000 | 28000 | 17.9 | 20.1 | 15000 | 24000 | |||||||||||||||||||

| 71911 | 55 | 80 | 13 | 23.7 | 27.4 | 15000 | 24000 | 22.4 | 26 | 14000 | 22000 | |||||||||||||||||||

| 71912 | 60 | 85 | 13 | 24.8 | 30.3 | 14000 | 22000 | 23.3 | 28.7 | 13000 | 20000 | |||||||||||||||||||

| 71913 | 65 | 90 | 13 | 25.1 | 31.9 | 13000 | 20000 | 23.6 | 30.2 | 12000 | 19000 | |||||||||||||||||||

| 71914 | 70 | 100 | 16 | 34.5 | 43.4 | 12000 | 19000 | 32.6 | 41.2 | 11000 | 18000 | |||||||||||||||||||

| 71915 | 75 | 105 | 16 | 25 | 45.6 | 11000 | 18000 | 33 | 43.2 | 95000 | 16000 | |||||||||||||||||||

| 71916 | 80 | 110 | 16 | 35.5 | 47.8 | 10000 | 17000 | 33.5 | 45.3 | 9000 | 15000 | |||||||||||||||||||

| 71917 | 85 | 120 | 18 | 46.5 | 61.9 | 9500 | 16000 | 43.8 | 58.6 | 8500 | 14000 | |||||||||||||||||||

| 71918 | 90 | 125 | 18 | 47.2 | 64.8 | 9000 | 15000 | 44.5 | 61.4 | 8000 | 13000 | |||||||||||||||||||

| 71919 | 95 | 130 | 18 | 47.9 | 67.8 | 9000 | 15000 | 45.2 | 64.1 | 8000 | 13000 | |||||||||||||||||||

| 71920 | 100 | 140 | 20 | 60.4 | 84.4 | 8500 | 14000 | 56.9 | 79.9 | 8000 | 13000 | |||||||||||||||||||

| 71921 | 105 | 145 | 20 | 61.4 | 88.2 | 8000 | 13000 | 57.8 | 83.5 | 7500 | 12000 | |||||||||||||||||||

| 71922 | 110 | 150 | 20 | 62.3 | 91.9 | 7500 | 12000 | 58.7 | 87 | 7000 | 11000 | |||||||||||||||||||

| 71924 | 120 | 165 | 22 | 73.7 | 107.6 | 7000 | 11000 | 69.5 | 101.9 | 6700 | 10000 | |||||||||||||||||||

| 71926 | 130 | 180 | 24 | 76.3 | 117.1 | 6700 | 10000 | 71.9 | 110.9 | 6000 | 9000 | |||||||||||||||||||

| 71928 | 140 | 190 | 24 | 78.9 | 126.4 | 6000 | 9000 | 74.4 | 119.7 | 5600 | 8500 | |||||||||||||||||||

| 71930 | 150 | 210 | 28 | 118.2 | 175.1 | 5600 | 8500 | 111.4 | 165.8 | 5000 | 7500 | |||||||||||||||||||

| 71932 | 160 | 220 | 28 | 123.6 | 191.2 | 5000 | 7500 | 116.5 | 181.1 | 4800 | 7000 | |||||||||||||||||||

| 71934 | 170 | 230 | 28 | 125.7 | 200 | 4800 | 7000 | 118.5 | 189.4 | 4300 | 6300 | |||||||||||||||||||

| 71936 | 180 | 250 | 33 | 159.7 | 249.1 | 4500 | 6700 | 150.6 | 235.9 | 4000 | 6000 | |||||||||||||||||||

| 71938 | 190 | 260 | 33 | 162.8 | 260.8 | 4300 | 6300 | 153.5 | 247 | 3800 | 5600 | |||||||||||||||||||

| 71940 | 200 | 280 | 38 | 198.4 | 311.4 | 3800 | 5600 | 187.1 | 294.9 | 3600 | 5300 | |||||||||||||||||||

| 71944 | 220 | 300 | 38 | 206.6 | 341.1 | 3600 | 5300 | 194.8 | 323 | 3200 | 4800 | |||||||||||||||||||

| 71948 | 240 | 320 | 38 | 219.2 | 384.2 | 3200 | 4800 | 206.7 | 363.8 | 3000 | 4500 | |||||||||||||||||||

| 71952 | 260 | 360 | 46 | 284.6 | 528.8 | 3000 | 4500 | 268.3 | 500.8 | 2600 | 4000 | |||||||||||||||||||

| 71956 | 280 | 380 | 46 | 288.7 | 554.6 | 2600 | 4000 | 272.2 | 525.5 | 2200 | 3600 | |||||||||||||||||||

Performance characteristics of spindle bearing: Ultra high speed, high stiffness, high carrying capacity, good running performance, easy mounting of universally matchable bearings, suitable for oil and gas lubrication or injection lubrication.

Applications of spindle bearing: CAEC super high speed single row angular contact ball bearings might be used in the fields of machine tools, textiles, automobiles, railways, metallurgy, chemicals, electronics, Industrial pumps, Compressors, Material Handling, Electric motors.

Product features of angular contact ball bearing:

1. High-quality bearing materials: CAEC adopts ultra-clean steel, high purity high-carbon chromium bearing steel GCr15 from a well-known domestic manufacturer, which can extend the life of the bearing by 80%.

2. High quality bearing rolling elements: The bearing balls provided by CAEC have good product performance to ensure the optimal bearing configuration and smooth operation at high speed and quiet. CAEC has a complete process production line, from powder ultrasonic pre-dispersion, mixture mixing, spray drying granulation, near-net-size molding, cold isostatic pressing, GPS-HIP combined sintering process, high-precision grinding and processing, total quality inspection to packaging. CAEC has a comprehensive quality control system, quality identification of raw materials and auxiliary materials, quality control of mixed materials, quality control of pressing and sintering, and quality control of finished products.

3. More suitable bearing cage: CAEC mostly adopts bakelite cage, which can more effectively reduce the friction between metal and bearing balls and extend the life of the bearing. CAEC can also choose more suitable bearing cage materials according to customer requirements and bearing applications.

4. Advanced lubrication technology: CAEC uses high performance grease and advanced lubrication technology to extend bearing life and improve bearing performance.

5. Ultra finished raceways:CAEC uses special honing to minimize noise, improve lubricant dispersion and increase bearing life.

6. Contact angle: CAEC ultra high speed precision bearings usually use 15°and 25° contact angles.

7. Accuracy grade: CAEC can offer the high precision angular contact ball bearings with P2, P4A, P4 grade.

CAEC Precision Bearing Quality Control and Assurance:

Austrian AICHELIN heat treatment equipment and long-life heat treatment process provide a strong guarantee for the continuous and reliable operation of bearings.

FAQ:

Q: Are you trading company or manufacturer?

A: CAEC is bearing manufacturer, the only first-class comprehensive research institute in China bearing industry.

Q: How do you control quality of bearing?

A: CAEC has established quality control systems for each kind of bearing and spindle. All products and services passed ISO9001-2008 Quality Certificate.

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic tube+ carton+ pallet). Accept design package when OEM.

Q: How long is the delivery time?

A: It will take about 10 to 40 days, depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have the forwarder.

Q: Is sample avaiable?

A: Yes, sample order is acceptable.

Q: Can we use our own LOGO or design on bearings?

A: Yes. OEM is acceptable. We can design the bearing with your requirements and use your own LOGO and package design.